Within a 9-month project, we developed the prototype of an area scanner, which was funded by the Bavarian program for the promotion of technology-oriented start-ups (BayTOU). In the course of development, we at Rasch-Diascan decided to combine the Sony α7R III system camera with a specialized industrial lens. Sony is the world's largest manufacturer of image sensors, which are built into many brands in the consumer market and in industrial cameras. It took another 12 months for the software-based process of «IR-Clean» to start with the market launch of an innovative scanning service. The camera scanner developed on this basis has the following technical features:

Weblog von Helmut Rasch, Inhaber von Rasch-Diascan

Area Scanner with «IR-Clean»

Technical Overview

First of all, the device is a film scanner for up to 35mm colour slide an negative film. The microcontroller based hardware supports an additional infrared scan used for digital dust and scratch removal. There are two types of series scanners:

- In a classical line scanner, a stepping motor moves a line scan camera over the template in order to scan it line by line. Due to the mechanical process, the requirements for the optics and the lighting are limited to one dimension or one line. The scanning process is associated with a comparatively large expenditure of time.

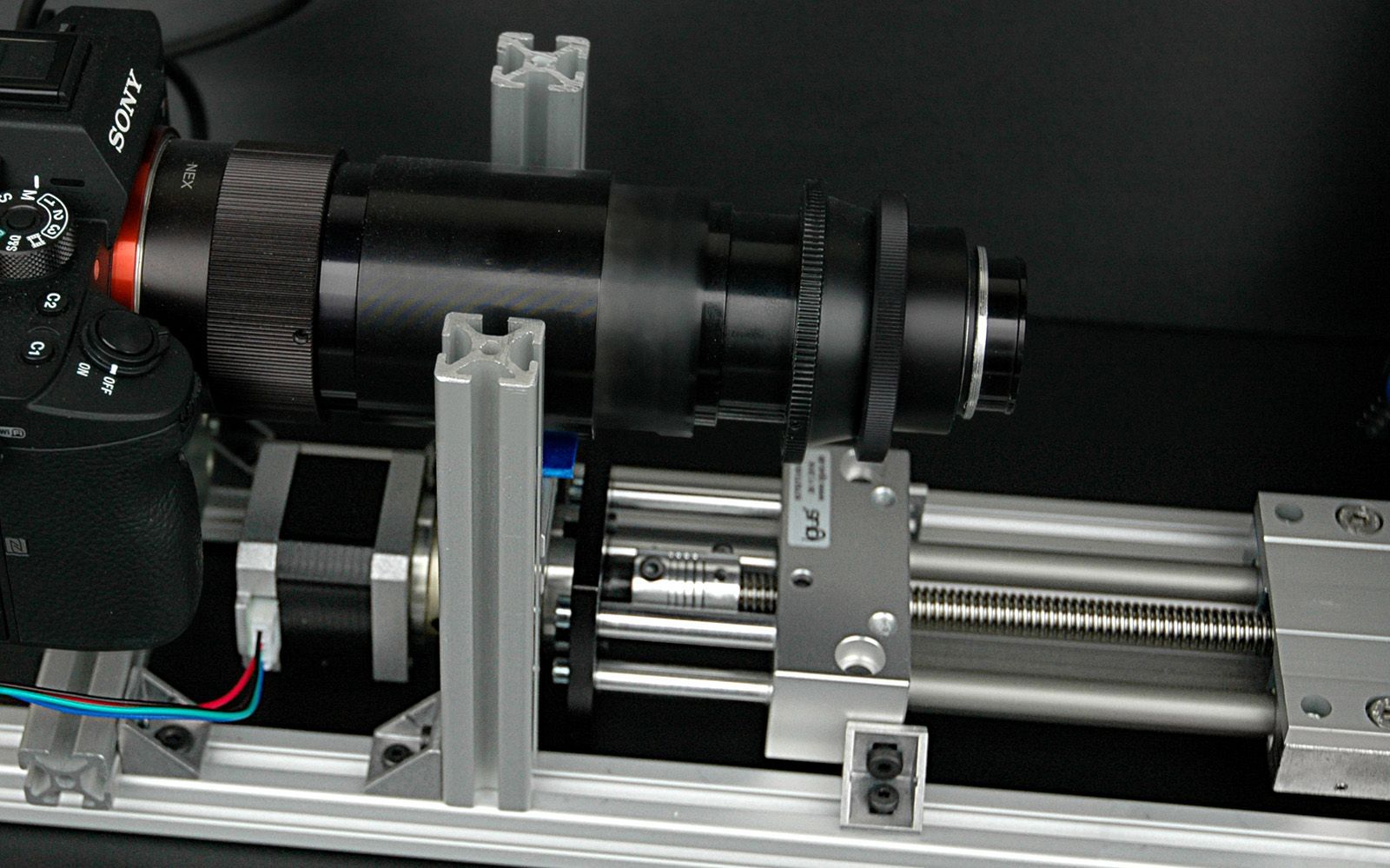

- In the case of an area scanner, the original is scanned two-dimensionally using an area scan camera. This purely photographic process is suitable for cost-effective processing speeds. The accuracy that can be achieved depends on the precision of the optical components used and the design.

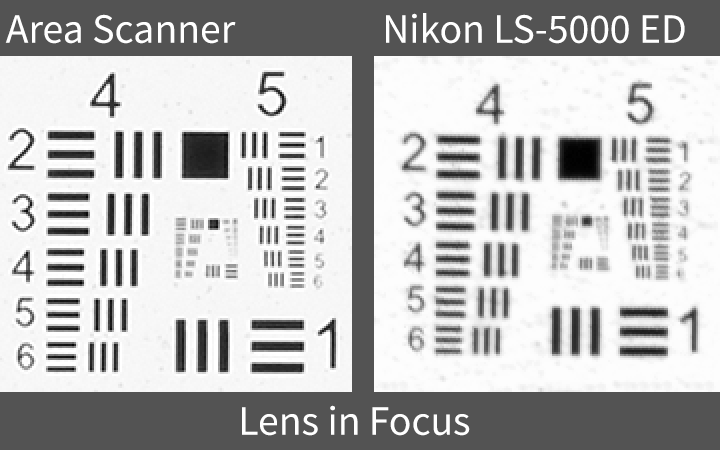

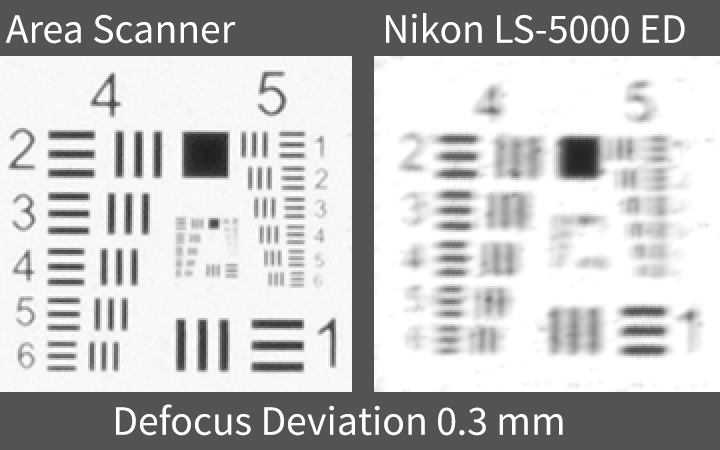

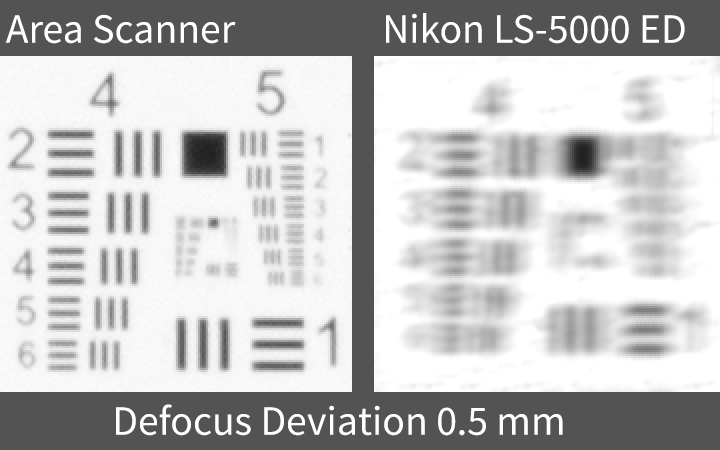

- Due to the more modern image sensor, the camera scanner achieves a significantly greater depth of field compared to the Nikon LS-5000 ED (Coolscan), which is still the reference today. This is a key benefit because of the film plane curvature.

- In contrast to a regular lens, a specialized reproduction lens provides high resolution all the way to the edges because it is calculated for a fixed magnification ratio. Most of these lenses are designed to avoid chromatic aberration as well (i.e. color fringes along high-contrast edges).

- A horizontal or vertical angular deviation between the slide holder and the focusing plane can be compensated by a high-precision tilting stage.

- An LED light field designed for industrial imaging is used as the light source. Using a patented process, it generates a very homogeneous light and delivers a continuous color spectrum.

- The in-house developed infrared cleaning «IR-Clean» adds a crucial feature to the camera scanner, which was previously only available for line scanners.

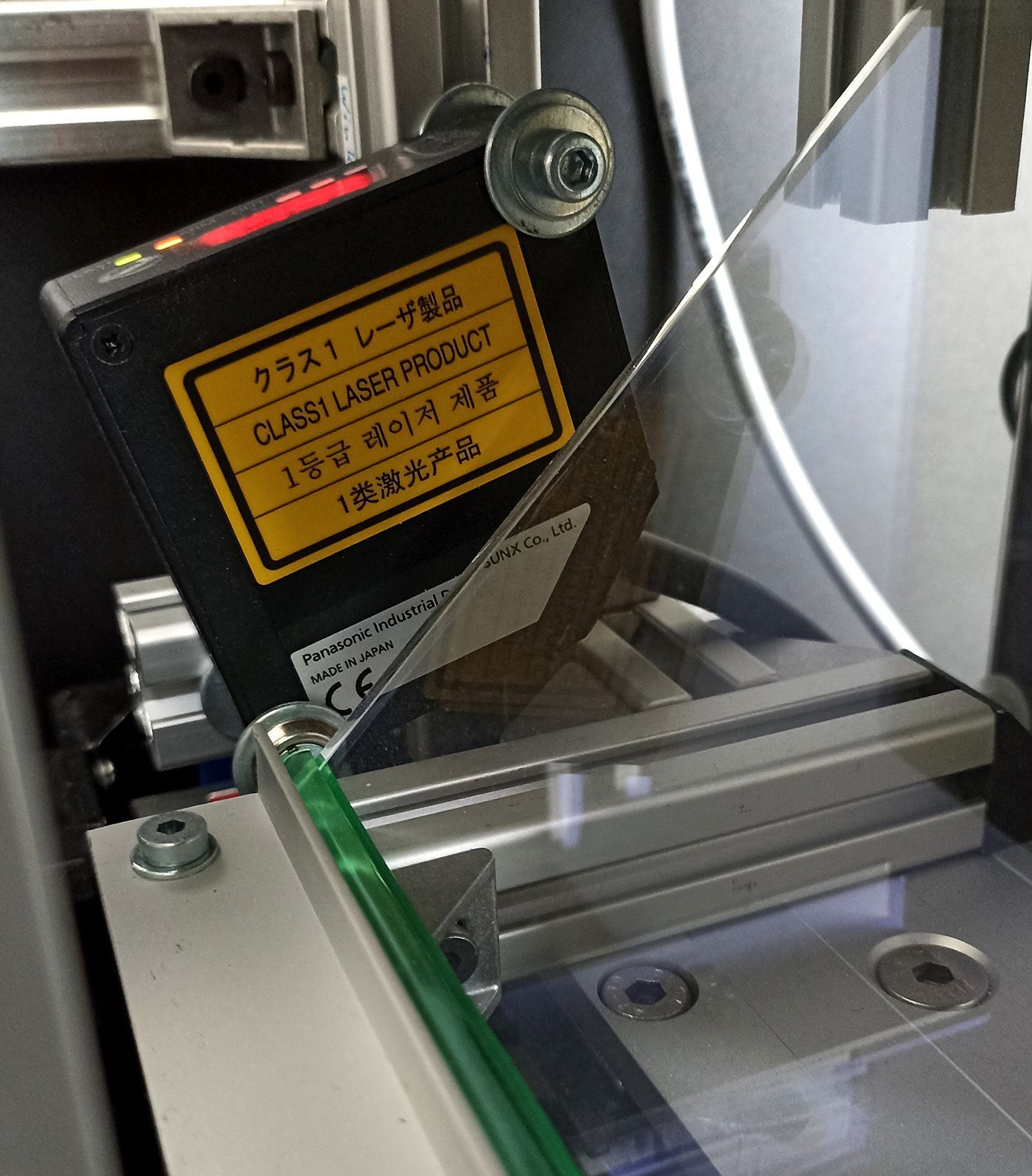

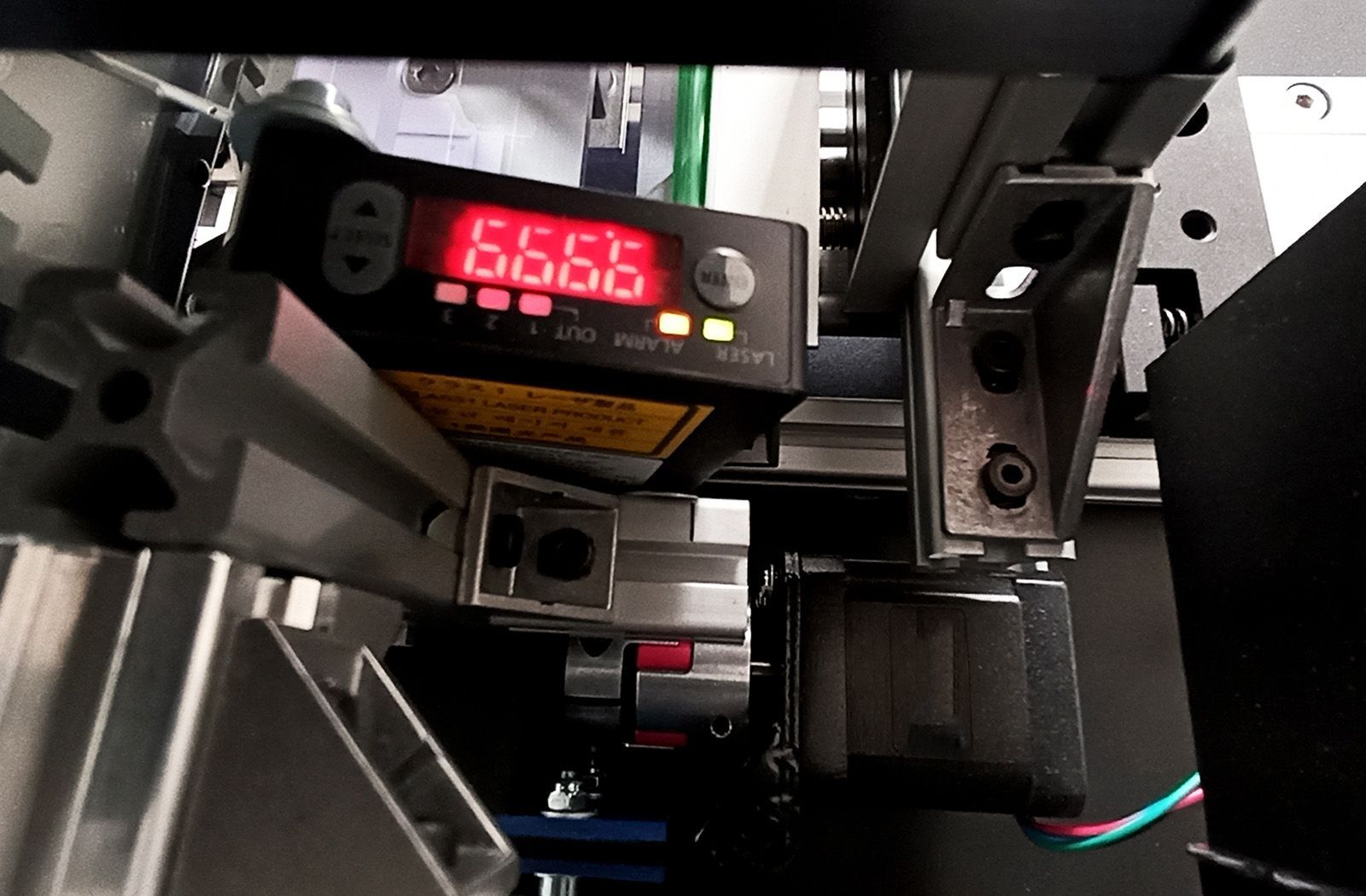

Laser Auto Focus

Bildtitel

Laser Sensor for Autofocus

Button

Bildtitel

Laser Sensor for Autofocus

Button

When a 35mm slide film is projected onto a full-frame sensor, the corresponding magnification ratio is 1:1. In this case, the calculated depth of field (DOF) is between 0.3 mm and 1.0 mm, depending on the aperture. To meet these specifications an autofocus is required but it is not available in case of a reproduction lens. Our in-house developed solution is a laser autofocus, which is able to detect and correct the deviation of the slide film from the focusing plane with slide mounts of different thicknesses with an accuracy of 10 µm.

Depth of Field in Comparison

Fig.: Slide with Line Pairs “USAF-1951 Target”

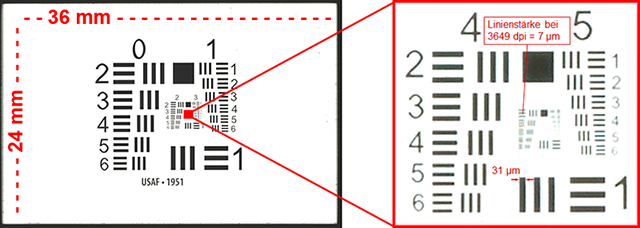

The resolution of a slide scanner can be measured using a so-called USAF-1951 target. The slide for the USAF-1951 resolution test contains line pairs of known line widths, which correspond to a certain resolution. Only the small red square on the left is of interest here, which is shown on the right as an enlarged section.

The following images give an impression of the depth of field by showing the results of an increasing defocus aberration. The optical system of the camera scanner works with a magnification ratio of about 0.94 compared to 1.25 for the Nikon LS-5000 ED (Coolscan). According to the mathematical relationship, the result confirms the larger depth of field at a lower magnification:

Bildtitel

Untertitel hier einfügenButton

Bildtitel

Untertitel hier einfügenButton

Bildtitel

Untertitel hier einfügenButton

Fig.: Results of an increasing Defocus Aberration

The resolution of the scans is around 5,800 x 3,800 pixels after cropping the black slide-mount-border and is thus clearly above the nominal resolution of 4000 dpi. However, the quality of slide scans cannot be reduced to a single value. More important is the effective resolution, which depends on high-quality hardware and on the workflow as well.

Hardware-Based Restoration with «IR-Clean»

Comparable to an X-ray, infrared light can pass through the colour emulsion of slides, while dust and scratches appear as dark structures in the infrared image. This information can be interpreted by «IR-Clean» to localize and remove defects accurately without affecting the original details or sharpness of the image. Infrared cleaning is by far the most reliable and efficient cleaning method to date. In contrast to software-based dust and scratch removal systems, all infrared cleaning solutions are hardware-based and were previously only available for selected line scanners. The following video explains how «IR-Clean» works:

With «IR-Clean» we have designed our own innovative solution, which uses the hardware of a cost-effective area scanner. IR-Clean 3.0 can process all color negative films and color reversal (slide) films including Kodachrome fully automated, a unique feature, which sets this technology apart from similar products. The workflow is optimised for high quality post-processing. For this reason, always three files are provided per scan:

- The Contrast Adjustment (TIFF, 48-bit) is the preferred standard image file in case of well-preserved footage. After the IT8 color calibration, there is no further intervention in the color balance. We offer

free samples for download in Technote 09.

- The Colour Adjustment (TIFF, 48-bit) is delivered as an alternative standard image file, which is able to improve color casts on older slides (see

Technote 05).

- The RGBi archive file (TIFF, 64-bit, AdobeRGB) for post-processing or re-ordering including full image area and scan-borders.

Last Update: 27.06.2023

Weitere interessante Beiträge: